Why Lean and Six Sigma Integrate?

We knew we wanted to have Six Sigma Tools, that was clear.

But we also decided that what really makes change in a businesses and cleaning are the Lean tools.

Putting in a pull system, reducing batch sizes, significantly changing setup times, all of a sudden everything starts to flow.

Those are the types of things we saw over time that really made a difference in cleaing services.

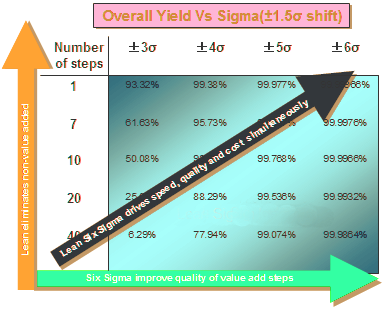

Six Sigma with Lean Is the Integration of Two Powerful Business Improvement Approaches

| Six Sigma (Precision + Accuracy +VOC ) |

Lean (Speed + Low Cost +Flexibility ) |

- Voice of the Customer (VOC)

- Statistical Process Control

- Design of Experiment

- Error-proofing

- Measurement Systems Analysis

- Failure Modes Effect Analysis

- Cause and Effect Analysis

- Hypothesis Testing

|

- Value stream mapping

- Bottleneck identification and removal

- “Pull” from the Customer

- Setup and queue reduction

- Process flow improvement

- Kaizen

- Supply Chain Strategy

- 5S

|

Integrating Lean and Six Sigma Initiatives

Lean and Six Sigma can co-exist independently, but the benefits of integration are tremendous.

- Single channel for employing limited resources

- One improvement strategy for the organization

- Highly productive and profitable synergy …while the pitfalls of not integrating them are formidable.

- Divided focus of the organization

- Separate and unequal messages for improvement

- Destructive competition for resources and projects

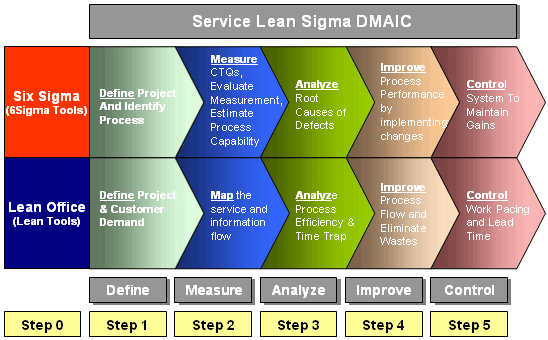

- Six Sigma is the “Unifying Framework”

- Six Sigma provides the improvement infrastructure

CEO Engagement

Deployment Champions

Green Belts, Black Belts, Master Black Belts

- Over-riding methodology: DMAIC, DMEDI, DMADV

- Lean provides additional tools and approaches to “turbo-charge” improvement efforts

Tools: Set-up reduction, 5S, Kanban, Waste Reduction

Approaches: Kaizen, Mistake

Discover More on Lean Cleaning

LEAN Principles

Six Sigma Principles

Lean Six Sigma Cleaning