Lean is a philosophy and set of management techniques focused on continuous “eliminating waste” so that every process, task or work action is made “value adding” (the real output customer pays for!!) as viewed from customer perspective. Lean “waste elimination” targets the “Eight Wastes” namely:

- Overproduction – Making more than what is needed by customer / market demand

- Over-processing - Doing more to a product/service (but not perceived as value by customer)

- Waiting – For material, information, people, equipment, procedures, approvals and more

- Transportation – Movement of products / items during or after production

- Defects – Errors, mistakes, non-complying products, services, documents, transactions

- Rework and Scrap – Products, transactions or outputs not meeting specifications and have to be fixed, redone, rectified, marked down or scrapped / unusable.

- Motion – Mainly people, document movement, searching etc.

- Inventory – Buffer stocks or resources (Raw, Work in process, FG, Bench staff etc.,)

- Unused Creativity – People knowledge and skills that are not utilized by the company.

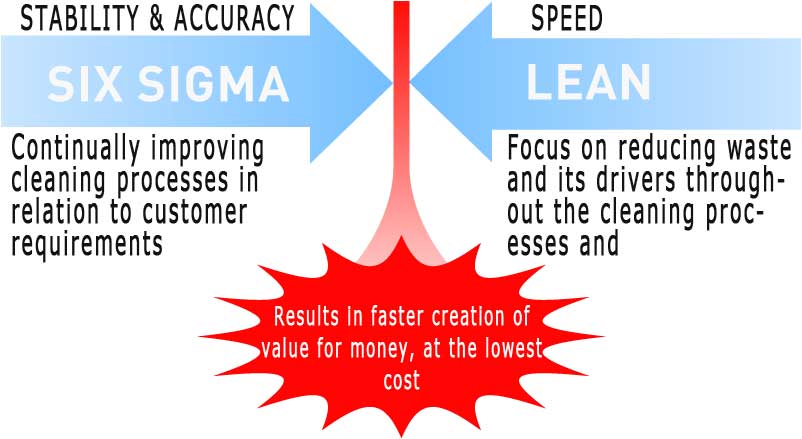

Wastes make the organisation slow, inefficient and uncompetitive. Lean methods help to remove / reduce waste and contributes to driving “business agility” (velocity) through smooth work flow across the organisation resulting in rapid fulfillment of customer needs in an optimum manner.

Discover More on Lean Cleaning

Six Sigma Principles

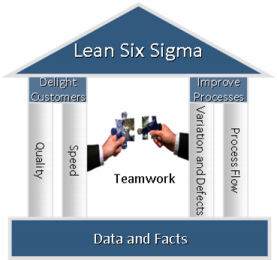

LEAN Six Sigma Principles

Lean Six Sigma Cleaning